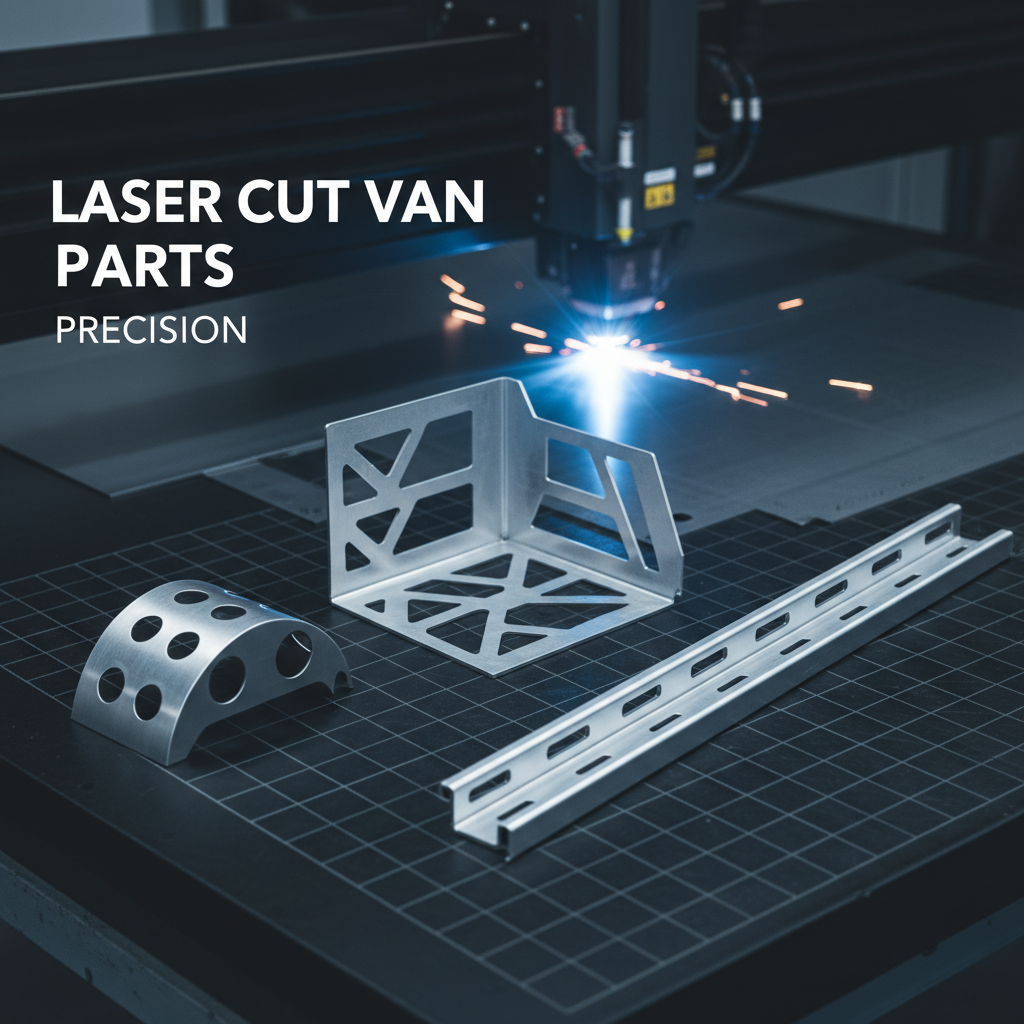

Laser cutting technology produces precision parts for aircraft, vehicles, and countless other applications. The technology enables complexity and accuracy that traditional machining can’t match.

How It Works

High-powered lasers cut through metal, plastic, and other materials with extreme precision. Computer control directs the beam along programmed paths. The process produces clean edges without mechanical stress.

Aviation Applications

Aircraft panels, brackets, and structural components benefit from laser precision. Complex shapes that would be difficult to machine become straightforward. Weight savings come from optimized part geometry.

Automotive Use

Van and vehicle manufacturers use laser-cut parts extensively. Custom interior components, exterior trim, and structural elements all benefit. The technology enables mass customization at reasonable costs.

Precision Advantages

Tolerances under a millimeter are routine. Repeatability ensures parts match specifications consistently. Quality control improves when human variation is removed from cutting operations.

Material Versatility

Different lasers cut different materials optimally. Steel, aluminum, plastics, and composites all respond to laser cutting. Material thickness affects speed and power requirements.

Cost Considerations

Setup costs favor larger production runs but decrease constantly. Prototyping and small batches are increasingly economical. The technology has democratized precision manufacturing.

Future Developments

More powerful and efficient lasers continue development. Integration with 3D printing creates hybrid manufacturing capabilities. The technology keeps advancing, opening new applications.